Tel:86-574-88169016 / 88169541

Tel:86-574-88169519 / 88169520

Tel:86-574-88169516 / 88169502

Operator:86-574-88169555

Fax:86-574-88169517

E-mail:sales@ngyc.com

Add:No.505 Qiming Road,Yinzhou Investment & Business Incubation, Ningbo,China.

Post Code:315104

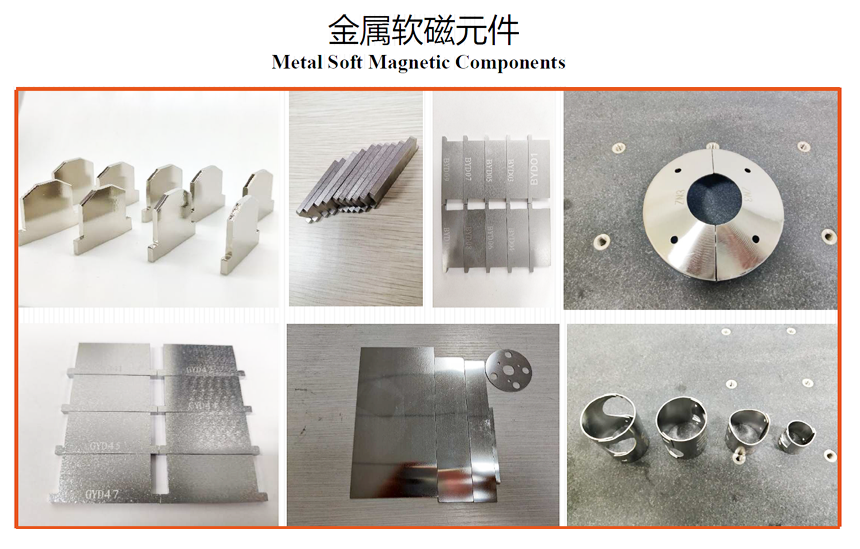

The Soft Magnetic Division of Ningbo Ninggang Permanent Magnetic Materials Co., Ltd. (NGYC) has long-term cooperation with domestic famous scientific research institutes and universities to conduct in-depth research and continuous improvement on the application and technical issues of soft magnetic products, and has independent intellectual property. The Soft Magnet Division uses high-quality electromagnetic pure iron, cobalt vanadium iron, permalloy and other metal soft magnetic materials as raw materials, specializing in the production of pole shoe yokes, transformer cores, magnet pole heads, inductor cores, magnetic shielding and other soft magnetic components and precision soft magnetic assemblies, and also ferrite cores. The development orientation of the Soft Magnet Division is to provide domestic and foreign customers with satisfactory soft magnetic products in the fields of electric power engineering, electronic information, precision measurement, scientific research, high-energy physics, etc., and also provides complete solutions such as magnetic field physical design, product structure optimization, and technical service support.

1)Electromagnetic Pure Iron Series

Electromagnetic pure iron is a high-quality special magnetic steel with an iron content of more than 99.5%. Its technical characteristics are as follows,

Low coercivity Hc, high permeability μ and high saturation induction Bs. It is used for occasions where high magnetic flux density is required under static low field and low frequency conditions, but it is not suitable for high frequency fields due to low resistance.

High purity, dense structure and uniform organization. The gas content of electromagnetic pure iron is related to the density, pure iron without hairline and airtight pure iron can be used in the fields that require extremely high vacuum degree and stable magnetic properties. Electromagnetic pure iron products without coating have poor corrosion resistance, and generally need to take coating protection measures.

The processing performance is good, and various mechanical processing such as turning, punching, bending, and welding can be performed. The surface quality of the processed electromagnetic pure iron components and components is also very good. But since the electromagnetic pure iron material is soft, in the process of production, quality inspection, turnover transportation, application installation, etc., attention should be paid to taking measures to prevent damage such as mechanical scratches.

Electromagnetic pure iron products are widely used in various iron cores, electromagnets, permanent magnet motors, DC motors, magnetic powder clutches, electrical equipment, automotive engines, magnetic shielding, instrumentation, electronic components, solenoid valves, magnetic separators, medical imaging, telecommunication equipment, power generation engineering, aerospace, accelerator and other fields.

![]() Electromagnetic Pure Iron Series Type Detailed Table.pdf

Electromagnetic Pure Iron Series Type Detailed Table.pdf

![]() Hysteresis Loop and Magnetic Properties of Pure Iron DT4E.pdf

Hysteresis Loop and Magnetic Properties of Pure Iron DT4E.pdf

2)Cobalt Vanadium Iron Series

The main elements of cobalt vanadium iron soft magnets are metal cobalt, iron, etc., the price is relatively expensive, and the main technical characteristics are as follows,

High saturation magnetic induction intensity Bs. Cobalt vanadium iron soft magnets has the highest saturation magnetic induction intensity (2.4T) in the existing soft magnetic alloys, the Curie point Tc is also very high, and the saturation magnetostriction coefficient is the largest, such as 1J22 can reach up to 60~100×10-6.

The characteristics of high saturation magnetic induction intensity Bs make it possible to achieve miniaturization in the production of electromagnetic equipment of the same power. High Curie point Tc enables the alloy to maintain good magnetic stability at higher temperatures. Large magnetostriction coefficient is suitable for making transducers, which can greatly increase its output energy and efficiency.

Low resistivity, high eddy current loss, not suitable for use at high frequency. Adding appropriate amount of Ni or V or other elements can improve its processability and oxidation performance, and most applications require coating protection.

Components and assemblies made of cobalt vanadium iron alloy are widely used in fields that require miniaturization and high working temperature, such as aviation electrical appliances, micro-motors, electromagnets, relays, motors, etc. The main domestic grades are: 1J21, 1J22, 1J27 and so on.

![]() Cobalt Vanadium Iron Series Type Detailed Table.pdf

Cobalt Vanadium Iron Series Type Detailed Table.pdf

![]() Hysteresis Loop and Magnetic Properties of Cobalt Iron 1J22.pdf

Hysteresis Loop and Magnetic Properties of Cobalt Iron 1J22.pdf

3)Permalloy Series

Permalloy refers to Ni-Fe alloy. The nickel content is adjustable in the range of 30-90%. It is a high-performance metal soft magnetic alloy which is widely used. Its main technical characteristics are as follows,

High magnetic permeability, low loss, small magnetostrictive coefficient, etc., The inductors and other components produced by Permalloy have strong anti-saturation ability, large inductance, good stability, small size, energy saving and high efficiency.

The processability is good, the surface quality of the processed components is good, and the welding performance is excellent. However, because the magnetic properties of Permalloy, especially the magnetic permeability, are sensitive to mechanical stress, the products after annealing are not suitable for collision, bending and other operations. Excessive installation stress should be avoided during application.

Contains more nickel elements, and has good corrosion resistance in general environment, especially high-nickel Permalloy, most products do not need special anti-rust treatment such as coating.

There are many grades of Permalloy, which can be divided into four categories according to the composition, 35%-40% NiFe alloy, 45-50% NiFe alloy, 50-65% NiFe alloy and 70-81% NiFe alloy. For each type, users can use the process parameters to adjust the hysteresis loop state of the raw material, and the user can choose flexibly according to their needs.

Commonly used Permalloy grades are 1J50, 1J79, 1J85, etc. The saturation magnetic induction intensity of 1J50 is slightly lower than that of silicon steel, but the magnetic permeability is dozens of times higher, and the iron loss is also 2-3 times lower. It is suitable for making high-frequency (400-8000Hz) transformers. 1J79 has good comprehensive performance and is suitable for applications such as high frequency and low voltage. The initial permeability of 1J85 can reach more than 100,000, which is suitable for applications such as weak signal low frequency or high frequency.

The main feature of low temperature Permalloy 1JL0 is that it has high magnetic properties especially the magnetic permeability at cryogenic temperatures such as below 2-77 K. The initial magnetic permeability is kept above 20,000. After special preparation and cyclic annealing, the initial magnetic permeability can reach up to more than 50,000, and is especially suitable for large-scale precision magnetic shielding components such as synchrotron radiation and free electron laser superconducting cavities used in cryogenic temperatures. The magnetic permeability of general 1J79, 1J85 will be greatly reduced in such a low temperature environment.

Permalloy is widely used in electronic communications, precision measurement, rectifiers, magnetic shielding components, relays, transformers, transformers, electromagnetic clutches and other fields.

![]() Permalloy Series Type Detailed Table.pdf

Permalloy Series Type Detailed Table.pdf

![]() Hysteresis Loop and Magnetic Properties of Permalloy 1J50.pdf

Hysteresis Loop and Magnetic Properties of Permalloy 1J50.pdf

![]() Hysteresis Loop and Magnetic Properties of Permalloy 1J79.pdf

Hysteresis Loop and Magnetic Properties of Permalloy 1J79.pdf

![]() Hysteresis Loop and Magnetic Properties of Permalloy 1J85.pdf

Hysteresis Loop and Magnetic Properties of Permalloy 1J85.pdf

4)Ferrite Series (Operated)

Soft ferrite is a non-metallic ferrite material with Fe2O3 as the main component, including MnZn, NiZn, etc., The application field is roughly divided into three types of materials, telecom ferrite, broadband and EMI ferrite, and power ferrite. Compared with other metal soft magnets, the main technical features of non-metallic soft ferrites are as follows,

High resistivity, hundreds to hundreds of thousands times higher than general metal soft magnets, especially suitable for medium and high frequency applications.

Soft ferrite can obtain high magnetic permeability without using scarce materials such as nickel. The main ceramic process is suitable for mass production, with low cost and insensitive to stress. The permeability is relatively stable with frequency.

The disadvantages of soft ferrite are low saturation magnetic flux density, low magnetic permeability and low Curie temperature, which limits its scope of use. Efforts are being made to improve it.

Soft ferrite is widely used in anti-electromagnetic interference, electromagnetic compatibility, electronic countermeasures, automatic control, aerospace, computing information, automotive transportation, consumer electronics, lighting systems and other fields.

浙公网安备:33021202001532号

浙公网安备:33021202001532号