Tel:86-574-88169016 / 88169541

Tel:86-574-88169519 / 88169520

Tel:86-574-88169516 / 88169502

Operator:86-574-88169555

Fax:86-574-88169517

E-mail:sales@ngyc.com

Add:No.505 Qiming Road,Yinzhou Investment & Business Incubation, Ningbo,China.

Post Code:315104

Samarium cobalt magnet is also called samarium cobalt permanent magnets, rare earth cobalt permanent magnets, etc. It is a magnetic material made of samarium, cobalt and other metal rare earth materials through proportioning, smelting into alloys, milling, pressing and sintering. With high magnetic energy product, extremely low temperature coefficient, the maximum working temperature can reach 350 ℃, and the negative temperature is not limited. When the working temperature is above 180 ℃, its maximum magnetic energy product and temperature stability and chemical stability are all better than NdFeB permanent magnet materials. It has strong corrosion resistance and oxidation resistance, so it is widely used in aerospace, microwave devices, communications, medical equipment, instruments, meters, various magnetic transmission devices, sensors, magnetic processors, motors, magnetic cranes and other fields.

| Partial Physical Properties of Sintering SmCo Magnet | |||

| Parameter Name | Unit | SmCo5 | Sm2Co17 |

| Density D | G/cm3 | 8.3 | 8.4 |

| Curie Temperature Tc | K | 1000 | 1100 |

| Vickers Hardness Hv | MPa | 450-500 | 550-600 |

| Compressive Strength δc | MPa | 1000 | 800 |

| Electronic Resistivity ρ | Ω.cm | 5~6×10-5 | 8~9×10-5 |

| Bending Strength δb | Mpa | 150-180 | 130-150 |

| Tensile Strength δt | Mpa | 40 | 35 |

| Thermal Expansion Coefficient α | (10-6/℃) | // 6⊥12 | // 8⊥11 |

Note: The typical values above are for reference only and cannot be used as a basis for judging material acceptance or rejection. Specific products may have different properties.

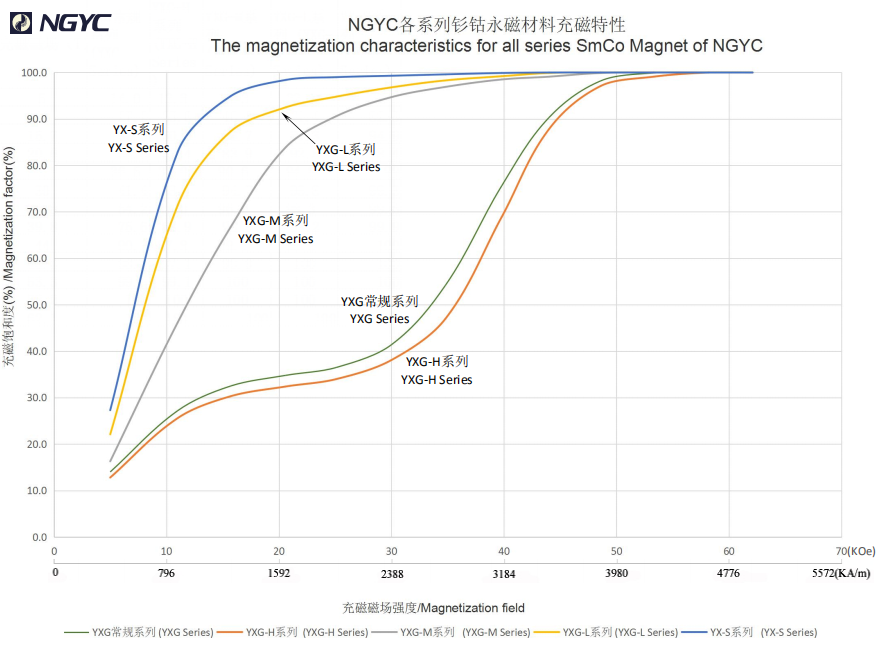

Note: Generally, the minimum saturation magnetization magnetic field required for sintering Sm2Co17 is 2-3 times the Hcj value of the material itself.

| Characteristic Comparisons of Permanent Magnetic Materials | |||||

| Materials Name | (BH)max (MGOe) | Hcj (KOe) | Temp. Coefficient of Br (%℃) | Max. Working Temp. (℃) | Anti-causticity |

| SmCo5 | 16-25 | 15-25 | -0.05 | 200-250 | Good |

| Sm2Co17 | 22-35 | 6-30 | -0.03 | 300-350 | Good |

| NdFeB | 26-52 | 12-30 | -0.11 | 80-200 | Bad |

| Ferrite | 3-4.5 | 3-4.5 | -0.19 | 200-300 | Good |

| AINiCo | 5-10 | 1-1.8 | -0.03 | 450-500 | Excellent |

(1) The sintered SmCo permanent magnetic materials have great brittleness and lacks ductility, so it should not be used as a structural part in design. SmCo5 has better mechanical and physical properties than Sm2Co17, and is slightly easier to process, and Sm2Co17 is more brittle. The magnetized SmCo magnets must be carefully extracted one by one during the use and assembly process, avoiding iron objects to avoid breaking the magnet, and two magnets attracting and colliding with each other will also damage the magnet or cause harm to the human body.

(2) Sintered SmCo magnets will have appearance defects such as slight missing corners due to slight collision during production, packaging and transportation. As long as it does not affect normal assembly or function, it will not damage the magnetic properties of the magnet and its stability and anti-demagnetization ability.

(3) Users who need to provide non-magnetized SmCo magnets must be familiar with the magnetization energy of their own magnetization equipment, so as to choose the grade

(4) If the designed product is used in acid-base or harsh environment, we can also provide products with electro-zinc, nickel, gold or epoxy resin. that can fully saturate the magnetization of the products.

Thank you very much for using our SmCo magnet products. Welcome to fax or email for consultation. We are always here to answer your technical questions and strive to provide you with high quality and competitive samarium cobalt permanent magnet products.

浙公网安备:33021202001532号

浙公网安备:33021202001532号